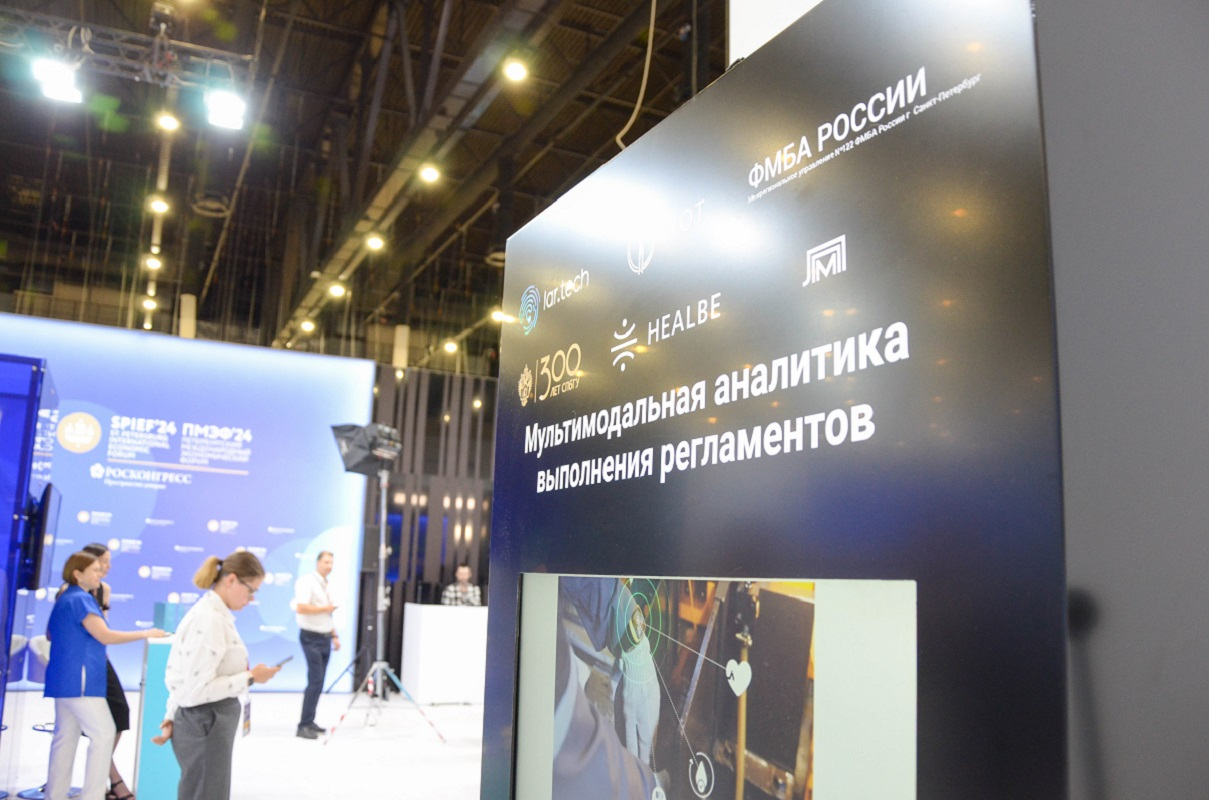

St Petersburg International Economic Forum 2024: St Petersburg University presents an AI control system for companies

St Petersburg University has presented a multimodal system for monitoring compliance with regulations, which can be used at industrial enterprises to ensure occupational safety and to monitor the performance of employees. The device is based on artificial intelligence methods, modern medical technologies, and the Internet of things. The system was developed by St Petersburg University together with the Federal Medical-Biological Agency and industrial partners: Healbe, Lartech, and Biot.

The video analytics software monitors compliance with the regulations and record violations in manufacturing or production environments and during equipment maintenance. It uses an external camera and a camera built into the helmet and work uniform. The operator can monitor all processes in real time, identify defects or possible violations of the production technology, and control the start and end times of the work.

Another part of the multimodal development is a smart bracelet and a mobile cardiograph, developed by the Centre for Artificial Intelligence and Data Science at St Petersburg University and Healbe for the Federal Medical Biological Agency. The AI-based analytics and data processing system constantly monitors the health status of workers and compare key indicators with an individual patient record.

Recently, St Petersburg University has received a grant to develop an artificial intelligence platform for things. The project will be implemented jointly with industrial partners. Among them are the following: Lartech, i.e. a developer and manufacturer of smart things, and the ITPS group of companies, which has developed a remote health monitoring service "BIOT" and other AI-based technologies.

When monitoring the heart rate, the devices rely on the personal indicators of the normal heart rate of a particular worker and transmit signals to the doctor for further monitoring and prescribing examination or treatment if necessary. The bracelet uses biometric sensors that measure fatigue, stress, hydration, heart rate, ECG, neuroactivity, and sleep quality to name just a few.

This comprehensive approach using AI methods and relying on personal data ensures compliance with the occupational safety standards at work and timely responses to the detected changes in the employee’s health status, which is especially important when working with hazardous substances. It can also significantly improve the quality of work performed and allocate employees’ time more efficiently.

Despite the high degree of automation of processes and devices, the key element of any production and the highest value is people. Without human efforts, not a single automated production line will work properly. Yet, people are also the main element of risk. It is important to use artificial intelligence methods to develop systems that ensure labour safety and take care of employee well-being.

Dmitriy Poltorak, General Director of Lartech

According to Sergey Mikushev, Vice-Rector for Research at St Petersburg University, the development of new AI-technologies is one of the priorities of St Petersburg University, which corresponds to the National AI Development Strategy, approved by the Executive Order of the President of the Russian Federation.

"Today, it is essential not only to introduce the existing technologies, but also to develop new approaches to the use of artificial intelligence to solve the most pressing problems in Russia. Among them are the digitalisation of the medical industry, labour safety, and increasing the production efficiency, because AI can significantly simplify and speed up the work of personnel and improve human health monitoring systems," said Sergey Mikushev, Vice-Rector for Research at St Petersburg University.

As part of the collaboration between St Petersburg University and industrial partners, a mobile device has also been developed for diagnosing industrial equipment, which uses the RFID tags to track key indicators of the devices and allows early detection and elimination of defects before serious problems arise. This reduces equipment downtime and cost of repairs and replacement of parts.