St Petersburg University Centre for Geology presents a new development – grouting mixtures for lifelong hydro isolation

Specialists from the small innovative enterprise ‘St Petersburg University Centre for Geology’ have developed a new type of grouting mix, which does not contain cement. Valery Trifanichev, one of the developers of the technology and chief engineer at the Centre for Geology, said that the unique composition makes it possible for the material to have a virtually unlimited service life. The material does not deteriorate under the pressure and weathering of fluids unlike its cement analogues.

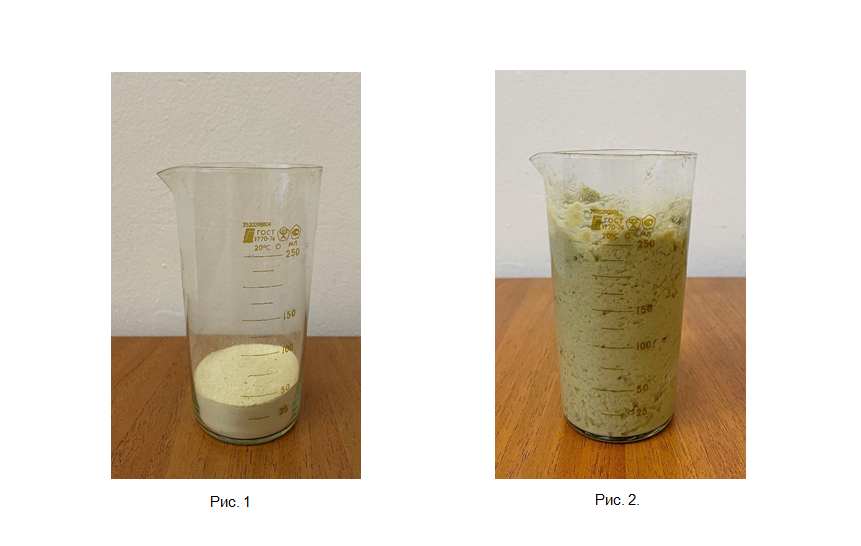

Grouting blends are visco-elastic mixtures that do not harden and are resistant to dynamic loads. When they are introduced into a porous mass or cavity and come into contact with water, plugging compounds can increase in volume many times. Additionally, once in the massif the material is capable of filling newly formed voids and cracks, taking their shape.

In their initial state, AE grouting mixtures constitute a finely dispersed powder. They can be used both to create loose hydro insulation screens and, in the form of special solutions, for injection (under pressure). The material was originally developed to provide stability to the walls of exploration wells and eliminate problems arising during their drilling.

'The grouting material and the technology of its application resolve many problems that were previously thought to be unsolvable. For example, it allows: the repair and elimination of well eruptions (sudden bursts of fluids to the surface); creation of impermeable barriers at operating facilities without disturbing their technological processes; and a virtually unlimited guarantee for waterproofing work, be it the elimination of uncontrolled water seepages or construction of impermeable barriers,' said Valerii Trifanichev.

The main advantage of the mixture is its unlimited service life. Conventional cement-based grouting mixtures, for example, suffer damage from various factors, such as dynamic loads or aggressive fluids. At the same time, these factors have almost no effect on AE grouting mixtures. Valerii Trifanichev observed that the material is capable of withstanding pressures of 5 MPa and even higher, according to test results.

The specialists of the St Petersburg University Centre for Geology are members of: the EurAsian Union of Experts in Subsoil in Subsurface Management (EUES); the expert commission of the Working Committee of the Eurasian Economic Commission; and the expert committees of the Ministry of Natural Resources and Environment of the Russian Federation.

Valerii Trifanichev added that the development has several applications: exploration drilling, mining, construction and the environment. It would also be important for Arctic exploration and development projects. For example, there are plans to use AE grouting mixtures to eliminate filtration on hydraulic structures built in permafrost conditions in the Arctic zone, such as the Sytykansky water power plant in the Republic of Yakutia.

Specialists of the St Petersburg University Centre for Geology presented another unparalleled development at the 15th RAO/CIS Offshore International Conference and Exhibition for Oil and Gas Resources Development of the Russian Arctic and Continental Shelf. It is a unit for separation of water-fuel emulsions, which allows purification of water from oil fractions without the use of reagents and high pressure. Its applications are diverse: at fuel spillages, for separating complex emulsions, or for gas purification. In the latter case, the unit can be used in industrial and other premises, not only for air purification, but also for the control of viruses and bacteria.

The St Petersburg Committee for Arctic Affairs commended the specialists of St Petersburg University Centre for Geology after the conference.