A St Petersburg University student has created a robot for diagnosing hot water pipes

The company "Hydrolex", which is headed by Dmitry Grokholsky a student of St Petersburg University, has created a robot for the diagnosis of heat supply pipes and hot water supply. The device is able to move inside the pipe at a speed of one meter per minute and, by analysing the magnetic field of the thermal pipeline, find corrosion defects on the walls. In August, the development is planned to be tested in real conditions: the robot will pass through three kilometres of pipes, which are serviced by SUE "TEK SPb".

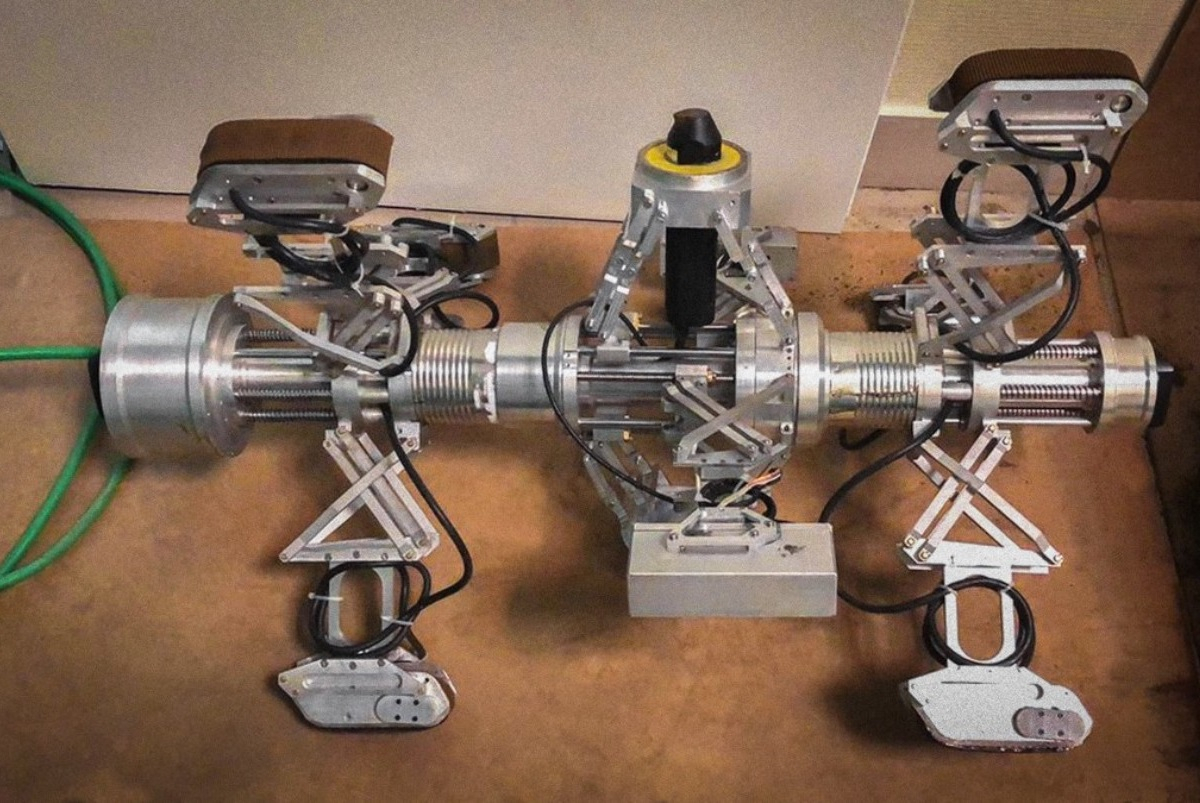

The diagnostic complex consists of three parts: six tracks for movement, special sensors, and software. The main feature of the robot is that it can analyse the changes in the electromagnetic field. A current that induces a magnetic field is passed through the surface of the tube; if there is no damage on the main line, then the magnetic field inside the pipe remains uniform, if there is - distortions appear that are picked up by sensors rotating around the axis of the device. Then the special programme compares the distribution of the transverse and longitudinal magnetic fields and determines the shape, size and even type of the defect.

"There is a very common problem: if there is an accident on the main pipe, a section of the pipe is unearthed, repaired and buried. And after a while there happens another accident, the burst of the main pipe, just five meters away from the previous place” explains Dmitry Grokholsky the general director of JSC "Hydrolex" and a student-mathematician at St Petersburg University. "To prevent this from happening, you can use our robot to analyse a large section of the pipe, for example, 50 meters on either side of the burst."

"This will help to identify and prevent all potential problems, which means saving government money that would be spent on repairs," said Dmitry Grokholsky

The robot is able to analyse pipes from 500 to 1000 millimetres in diameter - this task was put by the State Unitary Enterprise "TEK SPb" before the developers, but the invention can be adapted to other diameters. Sensitivity of the sensors allows you to receive electromagnetic signals at a distance of up to 30 millimetres from the main wall. At the moment, the robot can travel a distance of 150 meters; but, as the authors of the device note, this is due only to the length of the wires, so it can be increased if necessary. Interestingly, this technology can also be used in the oil and gas industry, in nuclear power engineering and for the diagnosis of various types of reservoirs.

Today, the ultrasonic method is most often used for the diagnosis of pipes, which requires much more labour-intensive preparation. First, the pipe must be filled with cold liquid, which means that repairmen need to take care of where to drain the coolant and where to get cold water from. Secondly, there should be no air "pockets", which for ultrasonic technologies are "dead zones". Thirdly, this method of diagnosis is not suitable for pipes with deposits on the walls: a porous surface is poorly transmitted by an ultrasonic signal. All these difficulties can be avoided if we use the method of magnetic diagnostics.

The creation and testing of a flaw detector is the first stage of work under a contract for the performance of research, development and technological work, which was concluded by ZAO Hydrolex and SUE TEK SPb. Its cost is 79 million roubles. Under the contract, developers should test the robot in real conditions in August - it will pass through three kilometres of St Petersburg pipes that are serviced by a heat and power company.