St Petersburg University mathematicians propose a method to economise on expensive polymers in oil production

Scientists of the Chebyshev Laboratory at St Petersburg University together with specialists from the Euler Mathematical International Institute and Gazprom Neft have developed a new technology for injecting water-soluble polymers into petroleum reservoirs. This method will help save up to 17% of expensive chemicals in crude oil production.

The research findings are published in the Journal of Computational and Applied Mathematics and the proceedings of the SPE Russian Petroleum Technology Conference 2021.

Sergey Tikhomirov is a member of the research group, Professor at St Petersburg University, Research Associate in the Chebyshev Laboratory and the Euler Mathematical International Institute. According to him, the world’s reserves of easily produced crude oil are rapidly declining. From many reservoirs, the oil producers have already taken out that part of the "black gold", for which it was enough to drill wells and inject water into some of them. At the same time, a large amount of crude oil still remains in the developed fields. It "sticks" to the walls of porous media like fat to a frying pan, and is not therefore pushed to the surface with water.

To recover the crude oil remaining in the reservoir, oil industry professionals use enhanced oil recovery methods. Instead of water, they often inject more viscous substances such as liquid polymers into the wells. However, this technology has a significant drawback. A chemical solution requires high costs, which significantly increase the cost of crude oil production.

Oil producers therefore proceed as follows: they inject a certain amount of liquid chemicals, called a slug, and then pour water.

Sergey Tikhomirov, Research Associate in the Chebyshev Laboratory and the Euler Mathematical International Institute

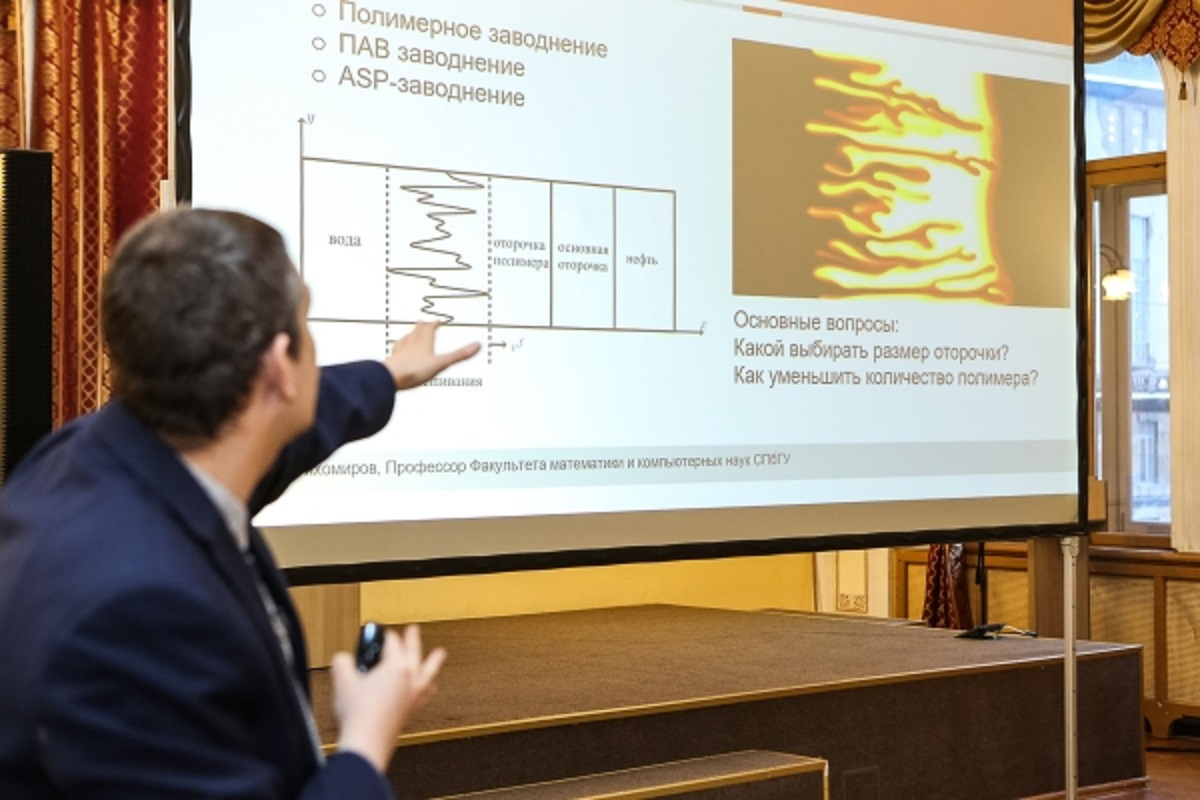

‘However, the difficulty is that water displaces a viscous solution unevenly. It forms uneven structures called viscous fingers in the slug. The viscous fingers develop and can prematurely break through the polymer solution, and then the oil, significantly reducing the effectiveness of the polymer,’ explained Sergey Tikhomirov.

The scientists of the Chebyshev Laboratory at St Petersburg University and the Euler Mathematical International Institute together with employees of the Gazprom Neft company managed to solve this problem. The researchers proposed using the method described by E. Claridge back in 1978 and gradually lowering the viscosity of the injected polymer. To do this, they created a special mathematical model that can help oil producers calculate the correct ratio of polymer concentration in the slug and water for successful crude oil production in different conditions. It will help to reduce the amount of polymer used and prevent early viscous fingering of the chemical solution.

‘Our model has an advantage over standard oil industry calculation models. We correctly predict the growth of viscous fingering. Our theoretical model always makes it possible to receive a correct pessimistic response: it shows that, under given conditions, the viscous fingering does not develop faster than the stated speed. This allows saving money without increasing risk. After all, if too little polymer solution is used, it will not work,’ said Sergey Tikhomirov.

The model created by mathematicians also allows setting the speed of viscous fingering at different concentrations of the polymer slug and the speed of the peak tailing, i.e. that part of the chemical solution that comes into contact with water. All this could not be calculated using classical formulae. The scientists tested and confirmed the performance of the new model using numerical simulations.

‘We thought: what will happen if the polymer cocktail is not immediately topped up with water? Is it worth initially injecting a slightly smaller volume of solution into the wells, adding it in several stages then, reducing the concentration of the injected agent each time? It turned out that this technology makes it possible to save up to 17% of polymers and ensure that the polymer slug does not break down. The next step is to test the technology in the laboratory. We hope to do laboratory tests in the near future together with Gazprom Neft,’ said Sergey Tikhomirov.

The researchers expect that in the future this development can be applied in real practice in crude oil production. According to Sergey Tikhomirov, in the future, oil industry specialists will be able to independently determine the number of concentration reduction stages necessary for the successful implementation of this technology in each specific field. The mathematical model created by the researchers will help oil producers. With its help, they will also be able to calculate the marginal benefit for each specific case.